Bark Characteristics of Acacia auriculiformis A. Cunn. ex Benth. and Acacia mangium Willd. From Industrial Plantation Forest

Downloads

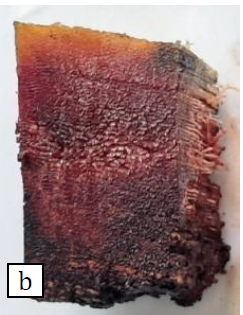

Increasing the value of bark can be known through the characteristics of the bark such as physical properties, the grade of fiber quality and the chemical composition of the bark. The purpose of this study is to find out the characteristics of the bark of the acacia plant species (i.e. Acacia auriculiformis and Acacia mangium) of Industrial Plantation Forest. The characteristics of the bark observed includes physical properties, quality grade of fiber and chemical composition. The results of this study showed that the bark density, thickness and water content of A. auriculiformis were 1.18g/cm3, 1.55 mm and 35.27% respectively, while, the bark density, thickness and water content of A. mangium were 0.95 g/cm3, 1.23 mm and 48.21% respectively. The fiber qualities of both plants are classified as grade III. The extractive substance levels of A. auriculiformis and A. mangium were 23.06% and 20.63%, respectively. Based on the analysis with GCMS it can be seen that the main compounds dissolve-hexane from species A. auriculiformis were 2-phenyl phenol 33.6% and palmitic acid 13.5%. In the species A. mangium the main compounds soluble n-hexane were palmitic acid 28.97% and oleic acid 21.43%. The results of the analysis showed that these two bark species could potentially to be adhesives materials, tanning agent, particle boards, and inhibitors at the rate of corrosion of steel.

Andianto, A. (2011). Perbandingan Ciri Anatomi Kayu Dan Kulit 3 Jenis Pulai. Jurnal Penelitian Hasil Hutan, 29(4), 356–368. https://doi.org/10.20886/jphh.2011.29.4.356-368

Arianti, D. C. (2011). Akasia (Acacia mangium Willd) Terhadap Kualitas Papan Partikel Yang Dihasilkannya. Departemen Hasil Hutan Fakultas Kehutanan Institut Pertanian Bogor, 60.

Direktorat Jendral Kehutanan. (1976). Vademecum Kehutanan Indonesia. Departemen Pertanian. Direktorat Jenderal Kehutanan. Jakarta.

Direktorat Jenderal Pengelolaan Hutan Produksi Lestari. (2018). Statistik Direktorat Jendral PHPL. http://release.phpl.menlhk.go.id/file/publikasi/1551870850-Statistik_2017_Full_Version.pdf

Fengel, D., & Wegener, G. (1983). Kimia Kayu. Terjemahan H. Sastrohamidjojo. Gadjah Mada University Press.

Gusti, D. R., & Farid, F. (2013). Ekstrak Kulit Kayu Akasia Sebagai Inhibitor pada Laju Korosi Baja Lunak dalam Media Asam Sulfat. 4.

Haroun, M., Khirstova, P., & Covington, T. (2013). Evaluation of Vegetable Tannin Contents and Polyphenols of some Indigenous and Exotic Woody Plant Species in Sudan. 7.

Herminiwati, H., Waskito, S., Purwanti, C. M. H., Prayitno, P., & Ningsih, D. (2015). Pembuatan bahan penyamak nano nabati dan aplikasinya dalam penyamakan kulit. Majalah Kulit, Karet, dan Plastik, 31(1), 15. https://doi.org/10.20543/mkkp.v31i1.180

Kasmudjiastuti, E. (2014). Karakterisasi kulit kayu tingi (Ceriops tagal) sebagai bahan penyamak nabati. Majalah Kulit, Karet, dan Plastik, 30(2), 71-78. https://doi.org/10.20543/mkkp.v30i2.128

Lempang, M. (2017). Basic properties and uses of agathis (Agathis hamii M. Dr.) wood from South Sulawesi. Jurnal Penelitian Kehutanan Wallacea, 6(2), 157–167. https://doi.org/10.18330/jwallacea.2017.vol6iss2pp157-167

Listyanto, T. (2016). Teknologi Pengeringan kayu dan Aplikasinya di Indonesia. Gadjah mada University Press. Yogyakarta.

Malrianti, Y., & Kasim, A. (2018). Tannins And Catechins Content Of Gambier (Uncaria Gambier Roxb) In Relation With Adhesive Qualities And Bonding Strength Of Cold Setting Glue. International Journal of Advanced Research, 6(12), 622–627. https://doi.org/10.21474/IJAR01/8181

Martawijaya, A., Kartasujana, I., Kadir, K., & Prawira, S. A. (1989). Atlas Kayu Indonesia. jilid I, Pusat Penelitian dan Pengembangan Kehutanan.

Mutiar, S., Kasim, A., Emriadi, E., & Asben, A. (2019). Studi awal tanin dari kulit kayu Acacia auriculiformis A. Cunn. Ex Benth. Dari hutan tanaman industri untuk bahan penyamak kulit. Majalah Kulit, Karet, dan Plastik, 34(2), 41. https://doi.org/10.20543/mkkp.v34i2.3967

Pandit, IKN., & Kurniawan, D. (2008). Anatomi Kayu: Struktur Kayu, Kayu Sebebagai Bahan Baku dan Ciri Diagnostik Kayu Perdagangan Indonesia. Fakultas Kehutanan. Institut Pertanian Bogor.

Rachmawati, O., Sugita, P., & Santoso, A. (2018). Sintesis Perekat Tanin Resorsinol Formaldehida dari Ekstrak Kulit Pohon Mangium untuk Peningkatan Kualitas Batang Sawit. Jurnal Penelitian Hasil Hutan, 36(1), 33–46.

Santoso, A., & Abdurachman, A. (2016). Karakteristik Ekstrak Kulit Kayu Mahoni Sebagai Bahan Perekat Kayu. Jurnal Penelitian Hasil Hutan, 34(4), 269–284.

Sjostrom, E. (1981). Kimia Kayu: Dasar-Dasar dan Penggunaan. Ed ke-2. Hardjono Sastrohamidjojo, penerjemah; Yogyakarta: FMIPA Universitas Gajahmada. Terjemahan dari: Wood Chemistry.

Suprapti, S., Santoso, E., Djarwanto, D., & Turjaman, M. (2012). Pemanfaatan Kompos Kulit Kayu Mangium Untuk Media Pertumbuhan Cendawan Mikoriza Arbuskula Dan Bibit. Jurnal Penelitian Hasil Hutan, 30(2), 114–123. https://doi.org/10.20886/jphh.2012.30.2.114-123

TAPPI. (1989). TAPPI Standards: Regulations and Style Guidelines. Atlanta: TAPPI Press.

Yanti, H., Syafii, W., & Darma, I. T. (2008). Sifat Anti Rayap Zat Ekstraktif Kulit Kayu Acacia auriculiformis A. Cunn. Ex Benth. 57.