Chemical Properties of Modified Mahogany Wood by Heat Treatment

Downloads

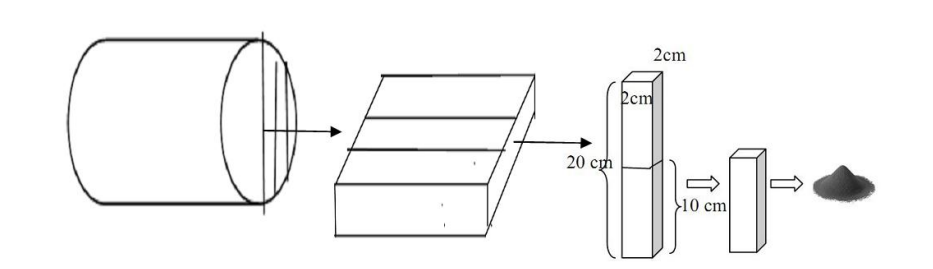

Mahogany woods from community forests generally have relatively low qualities due to lack of maintenance activities and for their young harvesting stage. Heat treatment is known as wood modification method that could improve the quality of the wood. The aim of this study was to determine the interaction effect of temperature and method of heat treatment on the chemical properties of young mahogany wood. Materials used in this research were mahogany wood boards from community forest which were heat-treated using oven and steam methods performed at the temperature of 90°C, 120°C, and 150oC for 2 hours. In this research, some chemical changes were analyzed. Results of the research showed that the interaction of temperature and heat treatment method gave a significant decreasing on the pentosan amount, and hot-water extractive solubility, particularly the steaming at 150oC. The increasing temperature of heat treatment significantly decreased the content of holocellulose, α-cellulose, hemicellulose, and pH values whereas it increased lignin content, extractives (cold-water and alcohol-benzene extractives) and solubility in 1% NaOH. Steaming method provided lower levels in the content of holocellulose, ethanol-benzene extract, cold-water solubility, and pH values compared to the oven heating. However, the steaming method over 1200C should be considered as it would reduce the wood strengths.

Akgul, M., Gumuskaya, E., and Korkut, S. (2007). Crystalline structure of heat-treated Scots pine [Pinus sylvestris L.] and Uludag fir [Abies nordmanniana (Stev.) subsp. bornmuelleriana (Mattf.)] wood. Wood Science and Technology 41, 281–289.

ASTM. (1984). Annual Book of ASTM Standards. American Scociety for Testing and Material. Race St., Philadelphia.

ASTM. (2007). Annual Book of ASTM Standards. Section Four Construction Volume 04.10 Wood. Baltimore.

Ates, S., Akyildiz, M. H., and Ozdemir H. (2009). Effects of heat treatment on Calabrian Pine (Pinus Brutia Ten.) Wood. BioResources 4(3), 1032-1043.

Browning, B.L. (1967). Methods of Wood Chemistry Volume II. Institute of Paper Chemistry. Winconsin.

Cao, Y., Jiang, J., Lu, J., Huang, R., Jiang, J., and Wu, Y. (2012). Color change of Chinese fir through steam-heat treatment. BioResources 7(3), 2809- 2819.

Chen, Y., Tshabalala, M.A., Gao, J., Stark, N.M., and Fan, Y. (2014). Color and surface chemistry changes of extracted wood flour after heating at 120°C. Wood Science and Technology 48, 137–150.

Ding, T., Gu, L., and Liu, X. (2011). Influence of steam preassure on chemical changes of heat-treated Mongolian pine wood. BioResources 6(2), 1880- 1889.

Esteves, B., Domingos, I. J., and Pereira, H.M. (2008). Pine wood modification by heat treatment in air. BioResources 3(1), 142-154.

Esteves, B., Nunes, L., Domingos, I., & Pereira, H. (2014). Comparison between heat treated sapwood and heartwood from Pinus pinaster. European Journal of Wood and Wood Products 72, 53–60.

Esteves, B. and Pereira, H.M. (2009). Wood modification by heat treatment: A review. BioResources 4(1), 370-404.

Esteves, B., Videira, R., and Pereira, H. (2011). Chemistry and ecotoxicity of heat-treated pine wood extractives. Wood Science and Technology (45), 661–676.

Fengel, D., dan Wegener, G. (1989). Kayu: Kimia, Ultrastruktur, Reaksi-reaksi. Gadjah Mada University Press (terjemahan). Yogyakarta.

Huang, X., Kocaefe, D., Kocaefe, Y., Boluk, Y., and Pichette, A. (2012). A spectrocolorimetric and chemical study on color modification of heat-treated wood during artificial weathering. Applied Surface Science 258, 5360–5369.

Kacíková, D., Kacík, F., Cabalová, I., and Durkovic, J. (2013). Effects of thermal treatment on chemical, mechanical and colour traits. Bioresource Technology 144, 669–674.

Karlinasari, L., Widyani, D., dan Nawawi, D.S. (2010). Kajian anatomi kayu dan kimia kayu kaitannya dengan sifat akustik kayu. Bionatura 12(3), 110- 116.

Kuzman, M.K., Kutnar, A., Ayrilmis, N., and Kariz, M. (2015). Effect of heat treatment on mechanical properties of selected wood Joints. European Journal of Wood and Wood Products 73, 689–691.

Lukmandaru, G. (2009). Sifat kimia dan warna kayu teras jati pada tiga umur berbeda. Jurnal Ilmu dan Teknologi Kayu Tropis 7(1), 1-7.

Martawijaya, A., Kartasujana, I., Kadir, K., dan Prawira, S.A. (2005). Atlas Kayu Indonesia. Pusat Penelitian dan Pengembangan Hasil Hutan. Mohammadi, N.M., Nemati, M., Samariha, A., Tabei, A., Ravanbakhsh, F., and Kiaei, M. (2011). Studying the effect of the age of a tree on chemical composition and degree of polymerization cellulose. Indian Journal of Science and Technology 4(12), 1679-1680.

Muslich, M., dan Krisdianto. (2006). Upaya Peningkatan Kualitas Kayu Hutan Rakyat sebagai Bahan Baku Industri. Prosiding Seminar Hasil Litbang Hasil Hutan. Bogor.

Rowell, R.M., Pettersen, R., Han, J.S., Rowell, J.S., and Tshabalala, M.A. (2005). Cell wall chemistry. Dalam: Rowell, R.M. (Ed), Handbook of Wood Chemistry and Wood Composites. CRC Press, Corporate Blvd., Boca Raton, Florida.

Seyedmohammadi, N., Nemati, M., Samariha, A., Tabei, A., Ravanbakshsh, F., and Kiaei, M. (2011). Studying the effect of the age of a tree on chemical composition and degree of polymerization cellulose. Indian Journal of Science and Technology 4(12), 1679-1680.

Srinivas, K., and Pandey, K. (2012). Effect of heat treatment on color changes, dimensional stability, and mechanical properties of wood. Journal of Wood Chemistry and Technology 32, 304–316.

Uribe, B.E.B. dan Ayala, O.A. (2015). Characterization of three wood species (oak, teak and chanul) before and after heat treatment. Journal Indian Academy of Wood Science 12(1), 54–62.

Varga, D., and van der Zee, M. E. (2008). Influence of steaming on selected wood properties of four hardwood spesies. Holz als Roh- und Werkstoff 66, 11-18.

Wahab, R., Khalid, I., Sudin, M., Sulaiman, O., Mohamed, A., and Kamal, N.A.M. (2011). Chemical, color and stength changes of hot oil treatment process on 15-year-old cultivated Acacia hybrid. Journal of Biological Sciences 3(6), 559-569.

Waliszewska, B., Prądzyński, W., Zborowska, M., Stachowiak-Wencek, A., Waliszewska, H., and Spek-Dźwigała, A. (2015). The diversification of chemical composition of pine wood depending on the tree age. Forestry and Wood Technology 91, 182-187.

Widmann, R., Fernandez-Cabo, J.L., and Steiger, R. (2012). Mechanical properties of thermally modified beech timber for structural purposes. European Journal of Wood and Wood Products 70(6), 775–784.

Widyorini, R., Khotimah, K., dan Prayitno, T.A. (2014). Pengaruh suhu dan metode perlakuan panas terhadap sifat fisika dan kualitas finishing kayu mahoni. Jurnal Ilmu Kehutanan 8(2), 65-75.

Windeisen, E., Strobel, C., and Wegener, G. (2007). Chemical changes during the production of thermo-treated beech wood. Wood Science and Technology 41, 523–536.

Yildis, S., Yildis, U.C., and Tomak, E.D. (2011). The effects of natural weathering on the properties of heat treated alder wood. BioResources 6(3), 2504-2521.

Zanuncio, A.J.V., Motta, J.P., da Silveira T.A., Farias, E.D.S., and Trugilho P.F. (2014). Physical and colorimetric changes in Eucalyptus grandis wood after heat treatment. BioResources 9(1), 292-302.

Zhang, Y., Yu, W., and Zhang, Y. (2013). Effect of steam heating on the color and chemical properties of Neosinocalamus affinis bamboo. Journal of Wood Chemistry and Technology 33, 235–246.

Zigon, J., Pizzi, A., Zhang, H., Sega, B., Cop, M., and Sernek, M. (2015). The influence of heat and chemical treatments of beech wood on the shear strength of welded and UF bonded specimens. European Journal of Wood and Wood Products 73, 685–687.