Freeboard and Trim Measurement: a Case Study of Landing Craft Tank Conversion to Ship Power Plan

Main Article Content

Abstract

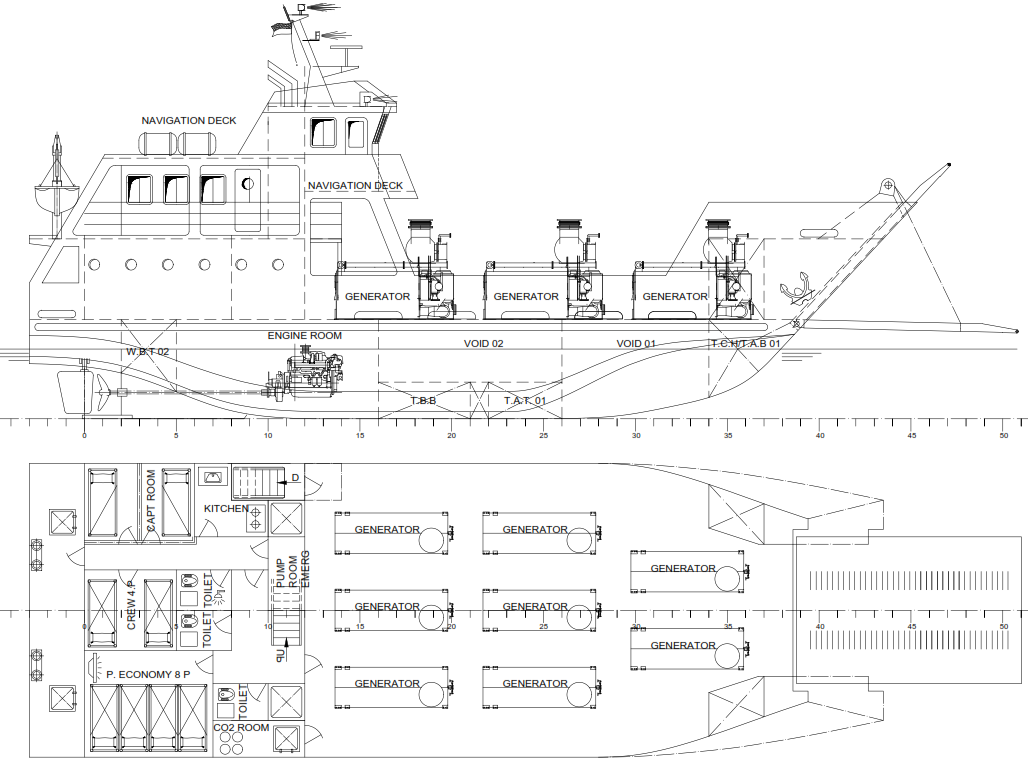

In this research, the ship power plan which is the result of a conversion from a landing craft tank is designed to meet the electricity needs in areas affected by a disaster or electricity crisis. So far, the government has chartered a similar ship from Turkey which is used to meet electricity needs in Indonesian areas which have been affected by the disaster and electricity crisis. This ship is modified to carry an electric generator which can later be sent to areas that need it. Two main focuses are the goal of this research, the first is to find the value of the freeboard and the second is the trim of the ship after the redesign. To achieve this goal, in this study a numerical calculation method was used to calculate the freeboard and trim values according to applicable standards. The results of the analysis show that the freeboard value is still safe, with the actual freeboard value being greater than the required freeboard (0.8 m > 0.44 m). For ship trim, the bow trim condition is obtained with a smaller LCG-LCB difference than the 0.05% LPP value (0.912 < 0.923). By looking at the results of these measurements, the condition of the ship's freeboard and trim is still in a fairly good category even though it has been converted from a landing craft tank to a ship power plant. This study can provide a reference for ship design before converting the actual ship so that it can carry out trim and freeboard tests to prevent build failures.

Downloads

Article Details

This work is licensed under a Creative Commons Attribution 4.0 International License.

Allow anyone to modify, improve, and make derivative works, even for commercial purposes, as long as they credit to you for the original work.

References

H. Gunawan Saputra, W. Amiruddin, and D. Chrismianto, “Jurnal Teknik Perkapalan Analisis Perbedaan Nilai Hambatan Redesain Kapal Ikan Kayu Tambak Lorok Menjadi Kapal Fiberglass,” J. Tek. Perkapalan, vol. 10, no. 4, pp. 41–48, 2022, [Online]. Available: https://ejournal3.undip.ac.id/index.php/naval

R. J. Ikhwani, A. Putri, and R. Aulia, “Effect of Temperature Variations of Corn ( Maize ) Oil Biodiesel on Torque Values and Thermal Efficiency of Diesel Engines,” vol. 7, no. 1, pp. 87–95, 2023, doi: 10.17977/um016v7i12023p087.

W. S. Suardi, Muhdar Tasrief, Samsu Dlukha Nurcholik, Amalia Ika Wulandari, “Testing the Inclination of an Industrial Diesel Engine Under Static Conditions According to the International Convention for the Safety of Life at,” Int. J. Mar. Eng. Innov. Res., vol. 8, no. 1, pp. 8–15, 2023, doi: http://dx.doi.org/10.12962/j25481479.v8i1.15749.

M. U. P. Suardi, Alamsyah, Andi Mursid Arifuddin, “EXPERIMENTAL ANALYSIS OF CASTOR OIL AND DIESEL OIL MIXTURES IN A 4-STROKE COMPRESSION COMBUSTION,” Int. J. Mech. Eng. Technol. Appl., vol. 4, no. 5, pp. 167–176, 2023, doi: 10.21776/MECHTA.2023.004.02.6.

R. J. I. Suardi, Wira Setiawan, Andi Mursid Nugraha Arifuddin, Alamsyah, “Evaluation of Diesel Engine Performance Using Biodiesel from Cooking Oil Waste ( WCO ),” J. Ris. Teknol. Pencegah. Pencemaran Ind., vol. 14, no. 1, pp. 29–39, 2023, doi: https://doi.org/10.21771/jrtppi.2023.v14.no1.p29-39.

L. P. Adnyani, R. F. Arrachman, and R. F. Arrachman, “Redesain Kapal Rede Untuk Analisa Hambatan,” Inovtek Polbeng, vol. 9, no. 1, p. 72, 2019, doi: 10.35314/ip.v9i1.903.

M. N. Misbah, D. Setyawan, and W. M. Dananjaya, “Construction strength analysis of landing craft tank conversion to passenger ship using finite element method,” J. Phys. Conf. Ser., vol. 974, no. 1, 2018, doi: 10.1088/1742-6596/974/1/012054.

W. Setiawan, R. Hermawan, and S. Suardi, “Analisa Potensi Angin Dan Cahaya Matahari Sebagai Alternatif Sumber Tenaga Listrik Di Wilayah Laut Sawu,” JST (Jurnal Sains Ter., vol. 4, no. 1, pp. 57–62, 2018, doi: 10.32487/jst.v4i1.453.

A. Alamsyah, M. D. Arwan, and A. I. Wulandari, “Analisa fatigue life konstruksi geladak pada kapal Landing Craft Tank menggunakan metode elemen hingga,” Turbo J. Progr. Stud. Tek. Mesin, vol. 10, no. 1, pp. 77–83, 2021, doi: 10.24127/trb.v10i1.1514.

S. Suardi, “Desain Ship Power Plant Sebagai Alternatif Krisis Listrik di Pulau Kagean, Jawa Timur,” JST (Jurnal Sains Ter., vol. 6, no. 2, pp. 68–73, 2020, doi: 10.32487/jst.v6i2.873.

S. Munakata et al., “An investigation into false-negative cases for low-freeboard ships in the vulnerability criteria of dead ship stability,” Ocean Eng., vol. 266, no. P5, p. 113130, 2022, doi: 10.1016/j.oceaneng.2022.113130.

H. Tu, K. Xia, E. Zhao, L. Mu, and J. Sun, “Optimum trim prediction for container ships based on machine learning,” Ocean Eng., vol. 277, no. November 2021, p. 111322, 2022, doi: 10.1016/j.oceaneng.2022.111322.

G. Cademartori, L. Oneto, F. Valdenazzi, A. Coraddu, A. Gambino, and D. Anguita, “A review on ship motions and quiescent periods prediction models,” Ocean Eng., vol. 280, no. May, p. 114822, 2023, doi: 10.1016/j.oceaneng.2023.114822.

I. M. Suwandiyana, A. Ahmadi, and P. Hartoko, “Risk Analysis of Landing Ship Tank Warships for Delivery of Logistic Assistance in Islanded Earthquake Location,” J. Asro, vol. 12, no. 04, pp. 127–135, 2021, [Online]. Available: http://asrojournal-sttal.ac.id/index.php/ASRO/article/view/429%0Ahttps://asrojournal-sttal.ac.id/index.php/ASRO/article/download/429/348

Yanmar, “6NY16LW|Auxiliary Engines|Product Concept|Marine Commercial|YANMAR Indonesia,” 2023. https://www.yanmar.com/en_id/marinecommercial/products/auxiliary_engine/6ny16lw/ (accessed Jun. 26, 2023).

H. Islam and G. Soares, “Effect of trim on container ship resistance at different ship speeds and drafts,” Ocean Eng., vol. 183, no. March 2018, pp. 106–115, 2019, doi: 10.1016/j.oceaneng.2019.03.058.

T. Hidayat, M. B. Firmansyah, and A. Y. Kyaw, “Impact of Axe Bow Hull Shape on Patrol Ship Resistance , Freeboard , and Trim,” vol. 2, no. February, pp. 21–27, 2023.

1966 and Protocol of 1988 International Convention on Load Lines, regulations for determining load lines. 1988.