Operational Performance Of Oily Water Separator Kl Sultan Hasanuddin 02 Pip Makassar In Protecting The Maritime Environment

Main Article Content

Abstract

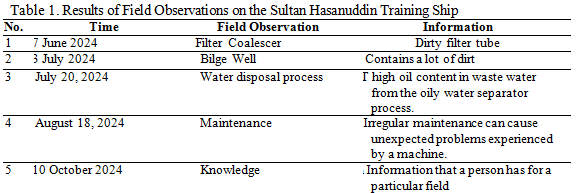

Sultan Hasanuddin 02 Training Ship which is a place for learning theory and practice of students at the Makassar Maritime Polytechnic. So that in supporting its operations requires periodic maintenance management that will ensure smooth and optimal performance in all supporting aspects. Likewise in the implementation of regulations that have required all ships to operate to install an Oil Water Separator that can separate oil and water before being dumped / falling into the sea. The use of Oil Water Separator must be maximized so that it can work properly, so it is necessary to carry out periodic and regular maintenance, the importance of maintenance management aims to evaluate the performance and effectiveness of the Oil Water Separator (OWS) in managing oil waste on ships by improving and increasing effectiveness and productivity in the utilization process to support smooth ship operations. Before making preparations in the maintenance stage, it is better to first make a proper plan and in accordance with the guidelines and also pay attention to field conditions both in terms of human resources and supporting spare parts and appropriate equipment. This study aims to evaluate the performance and effectiveness of the Oil Water Separator (OWS) in managing oil waste on the Sultan Hasanuddin training ship. By looking at the ship's ability to manage oil waste properly which will provide a positive image for the ship's Officers and Crew who are responsible for the environment, support sustainable practices and can increase trust from regulators and customers. Based on the results of field observations, there is still effectiveness in OWS performance with routine maintenance showing better separation efficiency than those that are rarely checked. However, the level of cleanliness of the effluent of the maintained OWS ranges from 5-10 ppm, while the unmaintained OWS reaches 20-50 ppm. The availability of spare parts and the level of personnel training are significant challenges.

Downloads

Article Details

This work is licensed under a Creative Commons Attribution 4.0 International License.

Allow anyone to modify, improve, and make derivative works, even for commercial purposes, as long as they credit to you for the original work.

Accepted 2025-02-03

Published 2024-11-27

References

[1] Wibowo, MA et al. (2017) 'The identification of construction waste at construction project life cycle', Advanced Science Letters, 23(3), pp. 2633–2635. doi: 10.1166/asl.2017.9196.

[2] Sulaiman, S. and S. Suharto,(2020). Commissioning Oily Water Separator System On New Building Ships. J. Mechanical Engineering, Vol. 15, no. 3, pp. 229–236, 2020.

[3] Toni Santiko, et al (2020). Analysis of Oil Content in Oil Water Separator in MT. Ontari. Jurnal Saintek Maritime, Volume 20 Number 2, March 2020 ISSN: 1412-6826 e-ISSN: 2623-2030

[4] Sugeng Haryadi et al (2023). Oil Water Separator (OWS) Maintenance Management to Prevent Marine Pollution on KM. LAWIT. Jurnal Matemarhttp://e-jurnal.amanjaya.ac.id/index.php/amanjayap-ISSN: 2745-6048, e-ISSN: 2745-4444. Engineering Study Program, Faculty of Maritime Affairs, AMNI Maritime University, Semarang, Indonesia

[5] Manungku Trinata P, et al (2021). Effectiveness of Modern Oil Water Separator (OWS) Technology on Ships in Overcoming Oil Pollution. Jurnal 7 Samudra p-ISSN: 2502-1621 Polytechnic of Shipping Surabaya e-ISSN: 2656-1611 Vol. 6, No.1, June 2021.

[6] Bennett, MA and RA Williams, (2004). Monitoring The Operation Of An Oil/Water Separator Using Impedance Tomography. Miner. Eng., Vol. 17, no. 5, pp. 605–614.

[7] Budi Utomo, et al. 2022. Analysis of the performance of the CYF-1.OY type oily water separator machine in the construction of a new 2000 GT ship using an experimental method. Indonesian Journal of Mechanical Engineering, Vol. 17 No. 2 (October 2022) Pages 1-6 1|JTMI.

[8] Ministerial Regulation Number 21 of 2010 concerning Maritime Environmental Protection

[9] Mohamad, DS (2019). Operation and Maintenance of Oil Water Separator at MT. Surya Chandra Pt. Suyandra Nusa.Jakarta. Paper