Analysis of Tensile Strength of Welding SS400 Steel with Varying Thickness

Main Article Content

Abstract

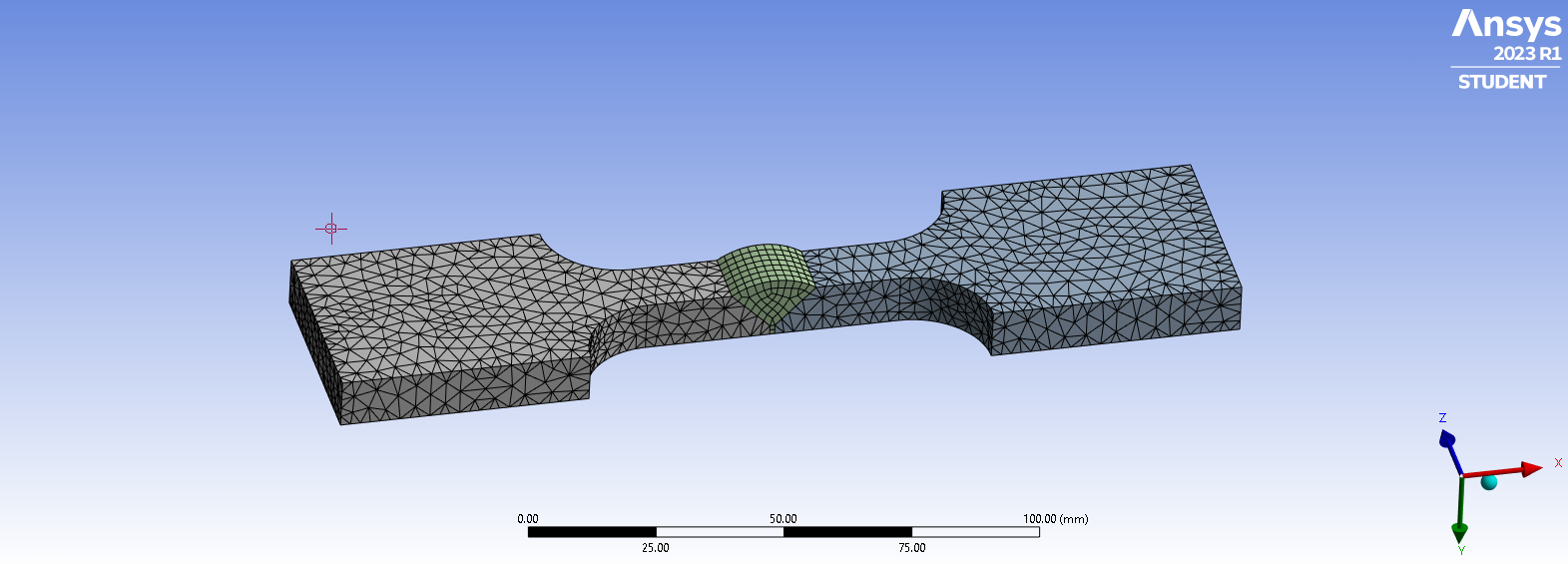

Technology in the construction sector is increasingly developing and advancing at this time. The construction that we often encounter is steel construction. In steel construction, we most often encounter metal joining or welding processes. Shield Metal Arc Welding (SMAW) is a metal joining process that uses electrical energy as a source of heat and is assisted by electrodes. In this journal, I modeled the welding results using Ansys Workbench. The modeling aims to carry out a tensile test simulation to determine the tensile strength of SS400 Steel with a plate thickness of 8 mm, 10 mm, and 12 mm. This research began with creating a model in ANSYS by referring to the SNI 8389:2017 standard. After the modeling is complete, then input the materials to be used, mesh the model with a size of 2 mm, and determine the fixed support and force of 100,000 (N/m2). Then we carried out a tensile test simulation to get the normal stress and total deformation values. The largest normal stress value was obtained on the 8 mm plate, which was 3845.4 MPa and the largest total permit value was obtained on the 8 mm plate, which was 0.28271 mm. The conclusion from this test is that the smaller the cross-sectional area of a model, the higher the pressure it will experience, so it will experience higher stress and will experience cooling more easily.

Downloads

Article Details

This work is licensed under a Creative Commons Attribution 4.0 International License.

Allow anyone to modify, improve, and make derivative works, even for commercial purposes, as long as they credit to you for the original work.

References

Adi Nugroho, Ekos Setiawan. “Pengaruh Variasi Arus Kuat Arus Pengelasan Terhadap Kekuatan Tarik Dan Kekerasan Sambungan Las Plate Carboon Steel ASTM”, Volume 3.No.2, 2018.

Azwinur, Muhazir. “Pegaruh Jenis Elektroda Pengelasan SMAW Terhadap Sifat Mekanik Material SS400”, Volume 17.No.2, 2019.

Helanianto, Epriyandi, Hairian Rahmadi, ”Pengaruh Variasi arus Pengelasan SMAW Terhadap Kekerasan Logam Induk dan Logam Las”, Vol.7 No.2, 2020.

Iqbal Hamdi, Taufiqullah, Herry Oktadinata, “Pengaruh Variasi Posisi Pengelasan Terhadap Distorsi dan Sifat Mekanik Hasil Pengelasan Baja SS400 Menggunakan Metode”, Vol. 8, No. 1, 2020.

Minto, Andhika Mayasari, Basuki, “Analisa Daerah Haz Hollow Terhadap Variasi Elektroda”. Volume XXVI.No.1, 2021.

Ahmad Sofyan, “Analisis pengaruh mesh pada distribusi tegangan Tarik dan bending plat baja karbon rendah dengan software solidworks”, 2021.

Nanda Julian, Untung Budiarto, “ Analisa Perbandingan Kekuatan Tarik pada Sambungan Las Baja SS400 Pengelasan MAG Dengan Variasi Arus Pengelasan dan Media Pendingin Sebagai Material Lambung Kapal”, Vol. 7, No. 4, 2019.

Naharuddin, Alimuddub Sam, Candra Nugraha, “ Kekuatan Tarik dan Bending Sambungan Las Pada Material Baja SM 490 Dengan Metode Pengelasan SMAW dan SAW” Vol. 6 No. 1, 2015.

Vuri Ayu Setyawati, Suheni, “ Variasi Arus dan Sudut Pengelasan Pada Material Austentic Stainless Stell 304 Terhadap Kekuatan Tarik dan Struktur Mikro “ Vol. 20 No. 2, 2016.

Awal Syahrani, Alimuddin Sam, Chairulnas, “Variasi Arus Terhadap Kekuatan Tarik dan Bending Pada Hasil Pengelasan SM490” Vol. 4 No. 2, 2013.