Application of Failure Mode and Effect Analysis (FMEA) Method in the Maritime Industry to Identify Potential Failures in Main Engine Components (Case Study on Vessel Xyz)

Main Article Content

Abstract

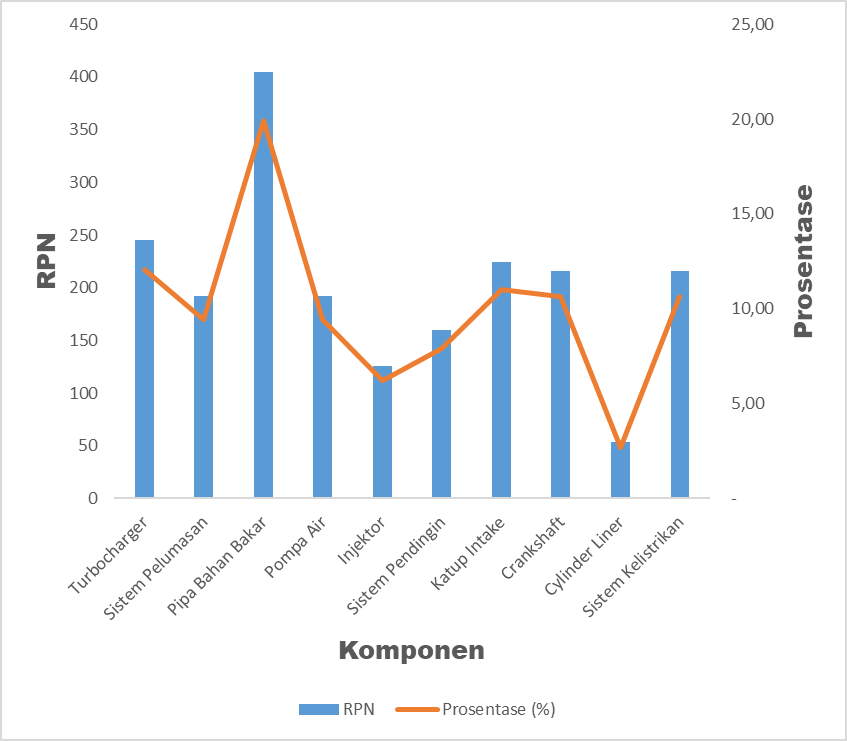

The main engine of a ship plays a crucial role in supporting its operations. Failure in this engine can have fatal consequences, both in terms of safety and economic impact. This study applies the Failure Mode and Effect Analysis (FMEA) method to the main engine of Ship XYZ to identify potential failure modes and calculate risk levels based on the Risk Priority Number (RPN). Operational data, interviews with the chief engineer, machinists, technicians, and historical failure analyses were used to assess the parameters of Severity (S), Occurrence (O), and Detection (D). The results indicate that fuel pipe leakage has the highest RPN value (405), followed by rotor damage in the turbocharger (245), and mechanical failure in the valve (224). Recommended improvements include enhancing maintenance of the fuel pipe system and conducting regular visual inspections, routine cleaning and lubrication, vibration inspections for turbocharger components, as well as using high-quality lubricants and cleaning carbon residue buildup on intake valves.

Keywords: FMEA, Main Engine, Potential Failure, Ship, RPN.

Downloads

Article Details

This work is licensed under a Creative Commons Attribution 4.0 International License.

Allow anyone to modify, improve, and make derivative works, even for commercial purposes, as long as they credit to you for the original work.

References

DAFTAR PUSTAKA

[1] Daryanto, Minto Basuki (2023) "Mitigasi Risiko Kegagalan Fungsi Peralatan Mesin Fresh Water Generator Dengan Pendekatan Failure Mode And Effect Analysis (FMEA) di Kapal Niaga Xyz" Jurnal Saintek Maritim, Volume 24 Nomor 1.

[2] Frank, Crawley. (2020). Failure modes and effects analysis (FMEA) and failure modes, effects and criticality analysis (FMECA). 103-109. doi: 10.1016/B978-0-12-819543-7.00012-4

[3] H. Hashimoto, S. Yoneda, Y. Tahara, dan E. Kobayashi, "CFD-Based Study on the Prediction of Wave-Induced Surge Force," Ocean Engineering, vol. 120, pp. 389-397, 2016.

[4] Ivo, Häring. (2021). 1. Failure Modes and Effects Analysis. doi: 10.1007/978-981-33-4272-9_7

[5] Jaroslav, Menčík. (2016). Failure Modes and Effects Analysis. doi: 10.5772/62364

[6] M. Iqbal, dan G. Rindo, "Pengaruh Anti-Slamming Bulbous Bow Terhadap Gerakan Slamming Pada Kapal Perintis 200 DWT," Kapal, vol. 13, no. 1, pp. 45-54, 2016.

[7] M. Iqbal, dan I. K. A. P. Utama, "An Investigation into the Effect of Water Depth on the Resistance Components of Trimaran Configuration," The 9th International Conference on Marine Technology, Surabaya, 2019.

[8] Mohammad Danil Arifin,Fanny Octaviani,Theresiana. D. Novita “Analisa Kegagalan Sistem Pelumasan dan Pemilihan Metode Perawatan M/E di Kapal Menggunakan Metode FMEA Dalam Rangka Menunjang Operasi Transportasi Laut di Indonesia”

[9] Marco, Sartor., Erik, Cescon. (2019). 8. Failure Mode and Effect Analysis (FMEA). doi: 10.1108/978-1-78769-801-720191008

[10] Rozar, Rayendra., Laila, Handika, Resfi. (2024). 5. Analisis Resiko Defect pada Proses Delivery dengan Metode Failur Mode and Effect Analysis (FMEA) di PT. Indo Perkasa Logistik. Jurnal Surya Teknika, doi: 10.37859/jst.v11i1.7222

[11] Yunus, Nazar., Ahmad, Wimbo, Helvianto., Jagat, Dewa, Maulana., Andrian, Wijayono., Verawati, Nurazizah. (2024). Analisis Permasalahan Teropong Menabrak Pada Mesin Shuttle GA615D Menggunakan Metode Failure Mode Effect Analysis. Jurnal Tekstil, 7(1):11-18. doi: 10.59432/jute.v7i1.70

[12] W. S. Vorus, "Vibration" in Principle of Naval Architecture Series, Jersey City: The Society of Naval Architects and Marine Engineers, 2018.