Fatigue Life Analysis of Mooring Cleats on The N219A Aircraft Floater Based on Numerical Simulation

Main Article Content

Abstract

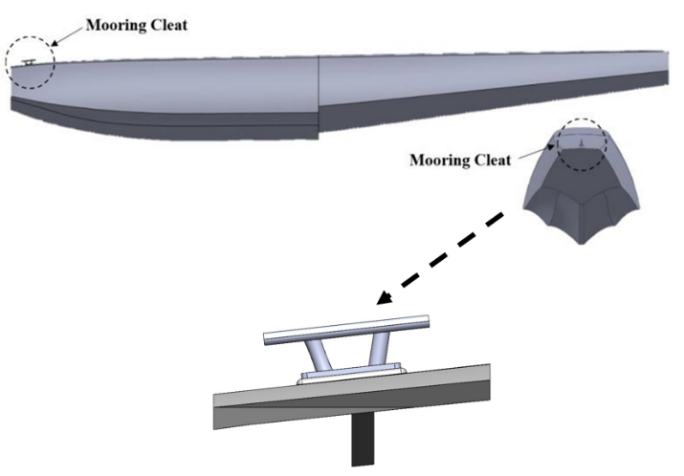

One of the procedures for rescuing a seaplane after an operational is to secure it, namely by mooring at an available port or mooring at a mooring buoy. This mooring buoy is considered a vehicle necessary for securing seaplanes in coastal conditions where it is not yet possible to build infrastructure in the form of an amphiport. To overcome this problem, seaplanes need to add a mooring cleat at the end of the bow of each float, which attaches the rope to the mooring buoy itself. So, it is necessary to study the strength of the mooring cleat itself when withstanding environmental loads. This study was carried out by modelling the mooring cleat using the finite element method to determine where the most significant stresses occur in the mooring cleat structure. Mooring cleats are modelled on deck thickness with varying thicknesses of 20mm and 40mm. The stress that occurred in the mooring cleat structure is then calculated using the Palmgren-Miner rule to determine the fatigue life of the mooring cleat for each variation. It was found that the largest von Misses stress experienced by the structure using 7075-T6 aluminium material was 147.87 MPa, which occurred in the mooring cleat, which was located on the 20mm deck thickness variation at the portside. Meanwhile, this variation's most extended fatigue life calculation occurred for the 40mm deck thickness variation on the portside with 514.43 years.

Downloads

Article Details

This work is licensed under a Creative Commons Attribution 4.0 International License.

Allow anyone to modify, improve, and make derivative works, even for commercial purposes, as long as they credit to you for the original work.

References

[1] M. L. Allokendek, D. M. Rondonuwu, and R. E. Sela, “Kajian Awal Pengembangan Wisata Bahari Berkelanjutan Di Kawasan Pesisir Perkotaan Manado,” vol. 13, no. 4, pp. 690–700, 2024.

[2] R. Arif and I. Qiram, “Peluang Dan Tantangan Seaplane Sebagai,” J. Penelit. Politek. Penerbangan Surabaya, vol. 6, no. 4, pp. 270–277, 2021.

[3] Federal Aviation Administration (FAA), Seaplane, Skiplane, and Float/Ski Equipped Helicopter Operations Handbook. Oklahoma City: U.S. Department of Transportation, 2004.

[4] R. D. Yulfani, D. M. Rosyid, W. H. Nugroho, E. Arianti, and A. Ghofur, “Numerical Analysis of Mooring Buoy for Securing N219A Aircraft in The Anchorage Area,” BIO Web Conf., vol. 89, 2024, doi: 10.1051/bioconf/20248904002.

[5] M. A. Mapariorio and S. Dlukha, “m 2301-9069,” vol. 17, no. 2, pp. 86–94, 2020.

[6] P. Corigliano, F. Frisone, C. Chianese, M. Altosole, V. Piscopo, and A. Scamardella, “Fatigue Overview of Ship Structures under Induced Wave Loads,” J. Mar. Sci. Eng., vol. 12, no. 9, p. 1608, 2024, doi: 10.3390/jmse12091608.

[7] R. Masoudi Nejad and F. Berto, “Fatigue fracture and fatigue life assessment of railway wheel using non‐linear model for fatigue crack growth,” Int. J. Fatigue, vol. 153, no. August, p. 106516, 2021, doi: 10.1016/j.ijfatigue.2021.106516.

[8] M. E. Lutema and A. M. Momhur, “Fatigue analysis of the railway wheels of the CRH2 high speed train due to random parameters,” … Comput. &Applied Res. …, vol. 13, no. 2, pp. 207–218, 2023, doi: 10.22061/JCARME.2023.9754.2315.

[9] Peraturan Presiden RI, “RPJMN 2020-2024,” 2020. [Online]. Available: https://www.bappenas.go.id/id/data-dan...dan.../rpjmn-2015-2019/

[10] W. U. Alifia and A. Sulisetyono, “Construction Design of the Float Considering the Free-Falling Impact of the Floatplane on Calm Water,” IOP Conf. Ser. Earth Environ. Sci., vol. 1276, no. 1, 2023, doi: 10.1088/1755-1315/1276/1/012060.

[11] S. Adhi Nugroho, H. Ardianto, and H. Setiawan, “Desain Struktur Float Pesawat Amfibi,” Tek. STTKD J. Tek. Elektron. Engine, vol. 6, no. 2, pp. 84–91, 2020, doi: 10.56521/teknika.v6i2.216.

[12] E. Arianti, W. H. Nugroho, R. D. Yulfani, E. Suwarni, and A. Hidayat, “Hydrodynamic Impact Load Prediction on Seaplane Float When Landing on the Water by Applying Slamming Load – RAO Approximation,” AIP Conf. Proc., vol. 2941, no. 1, 2023, [Online]. Available: https://doi.org/10.1063/5.0181474

[13] W. H. Nugroho, K. Priohutomo, N. J. H. Purnomo, M. M. Sugiarto, D. Hidayat, and Sahlan, “Estimation of Bending Natural Frequency of the Seaplane Float on the Water,” AIP Conf. Proc., vol. 2941, no. 1, 2023, doi: 10.1063/5.0181501.

[14] F. Dwi Juniarsah, S. A. Sitompul, and E. Yuniarti, “Simulasi Numerik Float Pesawat 19 Penumpang Dengan Struktur Carbon-Epoxy Composite Ketika Landing Di Permukaan Air,” J. Teknol. Kedirgant., vol. 8, no. 1, pp. 27–37, 2023, doi: 10.35894/jtk.v8i1.67.

[15] R. Ardiansyah and M. Adhitya, “Simulation of float of 19 passenger aircraft during landing on water surface,” IOP Conf. Ser. Mater. Sci. Eng., vol. 694, no. 1, 2019, doi: 10.1088/1757-899X/694/1/012005.

[16] N. Shabrina et al., “Session Assessment of Seaplane Operations: The Case of Marine Tourism Development on Gili Iyang Island, Indonesia,” IOP Conf. Ser. Earth Environ. Sci., vol. 1166, no. 1, pp. 1–14, 2023, doi: 10.1088/1755-1315/1166/1/012050.

[17] W. H. Nugroho, B. Riset, I. Nasional, N. Firdaus, I. Agency, and B. Ali, “IJEScA,” no. May, 2019.

[18] “CLNK150.pdf,” Float Your Boat. [Online]. Available: https://floatyourboat.co.uk/product/nordik-cleat/

[19] D. Ahmed et al., “A Fuzzy Logic Based Model to Predict the Fretting Fatigue Life of Aerospace Al7075-T6 Alloy,” Casp. J. Appl. Sci. Res., no. 12, pp. 39–48, 2012, [Online]. Available: http://www.cjasr.com

[20] N. Noraphaiphipaksa, P. Poapongsakorn, A. Hasap, and C. Kanchanomai, “Failure analysis of pressure vessel with sight ports using finite element analysis,” Eng. Fail. Anal., vol. 117, no. August, p. 104791, 2020, doi: 10.1016/j.engfailanal.2020.104791.