Analysis of The Effect of mooring Depth & Fatigue Damage on Mooring Line FPSO Ship Azurite In The Masela Block

Main Article Content

Abstract

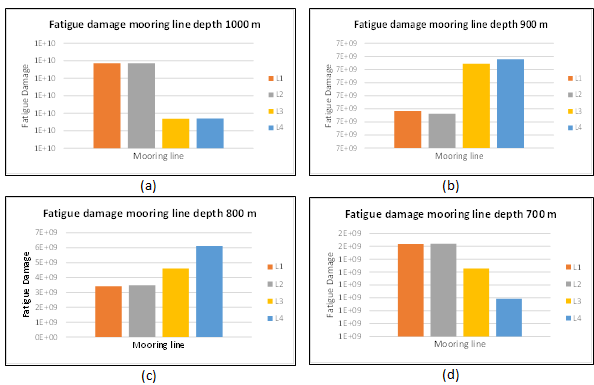

Oil & gas drilling in the open sea cannot be avoided with the use of FPSO. Floating Production Storage and Offloading (FPSO) is a facility in the form of a floating production storage and unloading vessel in the form of crude oil and natural gas originating from the seabed. The selected type of floater that will be operated in the Abadi field, Masela Block, Arafura Sea is the Azurite FPSO ship. In its operation, the FPSO will not be separated from the influence of dynamic loads such as sea waves, ocean currents and wind on the mooring rope structure periodically. This may cause damage to the structure mooring line which influences the performance of the structure. The aim of this research is to analyze motion trajectory (surge and sway), mooring line stress, and fatigue damage on the mooring system catenary by making comparisons using variations in mooring depth. Dimensions mooring line type chain on fairlead with six (6) variations in mooring depth, namely 1000, 900, 800, 700, 600 and 500 meters which will then be analyzed fatigue damage from mooring line the. Observation result Motion Trajectory It was found that the shallower the mooring depth mooring line then value ∆Offset or movement surge & sway will get bigger. Meanwhile in observations Mooring Line Stress and Fatigue Damage obtained both are directly proportional where the greater the tension mooring line then the ratio of damage that occurs due to fatigue in the structure will also be greater. This is because the mass of the rope used is not proportional to displacement boat. And in this numerical analysis simulation it only reaches the initial movement, namely at 100 seconds, where the ship's condition has not yet reached the stable condition it should be.

Downloads

Article Details

This work is licensed under a Creative Commons Attribution 4.0 International License.

References

. F. M. Assidiq, D. Paroka, M. Z. Muis, dan S. Klara, “Fatigue Analysis of Catenary Mooring System due to Harsh Environment in Head Seas", EPI International Journal of Engineering, Vol. 1, hal. 30-38, 2018.

J. Sade, “Literature Study Of The Effectiveness Of Flexible Pads As Submarine Pipeline Protection Due To Anchor Falls”, CBCER, vol. 1, no. 2 Desember, pp. 1–9, Dec. 2023.

F. Husain, “Impact and Failure of Internal Pressure of Pipe Connections C Influenced by Sea Water”, CBCER, vol. 1, no. 2 Desember, pp. 68–77, Dec. 2023.

H. Hamzah, “Study Of The Effectiveness Of Subsea Pipeline Leak Detection Methods”, CBCER, vol. 1, no. 2 Desember, pp. 45–56, Dec. 2023.

. Mahdarreza A, “Analisis Perilaku Floating LNG Pada Variasi Metocean Terhadap External Turret Mooring System Berbasis Simulasi Time Domain,” Surabaya. Tugas Akhir Jurusan Teknik Kelautan ITS 2010.

M. F. Bin Yusup, “Risk Evaluation and Damage Mitigation in Subsea Pipelines: A Literature Review of Concepts, Applications, and Challenges”, CBCER, vol. 1, no. 2 Desember, pp. 97–100, Dec. 2023.

M. Riayadh, “Literature Review on Integrity Management of Subsea Pipelines Operating Beyond Design Life”, CBCER, vol. 1, no. 2 Desember, pp. 88–92, Dec. 2023.

J. Sade, “Review of Marine Pipe Repair Methods in Indonesia”, CBCER, vol. 1, no. 2 Desember, pp. 10–17, Dec. 2023.

F. Husain, “Reliability Analysis Of Subsea Pipelines In High Wave Random Conditions”, CBCER, vol. 1, no. 2 Desember, pp. 78–83, Dec. 2023.

. N. Arifannisa, N. Syahroni, dan M. Mustedjo, “Analisis Umur Kelelahan Pada Anchor Chain Single Point Mooring 3”, Jurusan Teknik Kelautan, Fakultas Teknologi Kelautan, Institut Teknologi Sepuluh November, Hlm. 30, 2016.

. Zhang, X., Li, Y., & Li, C. "Influence of water depth on the dynamic response of FPSO mooring systems." Ocean Engineering, 166, 1-13, (2018).

T. Rachman, “Feasibility Study Of Subsea Pipeline Crossing Plan”, CBCER, vol. 1, no. 2 Desember, pp. 57–67, Dec. 2023.

H. Hamzah, “Study On The Application Of The Articulated Concrete Block Mattresses Method As Subsea Pipeline Protection”, CBCER, vol. 1, no. 2 Desember, pp. 37–44, Dec. 2023.

. Wu, Y., & Li, Y. "Fatigue damage assessment of mooring lines for deepwater FPSOs in the South China Sea." Ships and Offshore Structures, 14(2), 143-157, (2019).

. Sutarto, T. A., & Suherman, T. "Numerical study on the mooring system of FPSO in the deepwater Masela Block." Procedia Engineering, 170, 191-198, (2017).

. Peng, X., & Hong, S. "Fatigue damage analysis of mooring lines for FPSO in deepwater Masela Block." Journal of Offshore Mechanics and Arctic Engineering, 142(3), (2020).

. Zhu, L., & Zhao, Y. "Dynamic analysis of mooring system for FPSO in the Masela Block." Marine Structures, 48, 42-57, (2016).

A. Y. Kyew, “Problems and Solutions in Improving Subsea Pipeline Competency and Quality: A Comprehensive Literature Review”, CBCER, vol. 1, no. 2 Desember, pp. 93–96, Dec. 2023.

S. Rahman, “Vibration Characteristics and Reduction Analysis of the Lifting Pipe Below Sea Wave”, CBCER, vol. 1, no. 2 Desember, pp. 18–28, Dec. 2023.

N. Zin Latt, “ Literature Review of Concepts, Applications, and Challenges in Subsea Pipeline Risk and Reliability Management”, CBCER, vol. 1, no. 2 Desember, pp. 84–87, Dec. 2023.