Comparative Numerical Analysis Fatigue Damage Based On Variation In Quantities Mooring Line On Aker Smart 2 FPSO

Main Article Content

Abstract

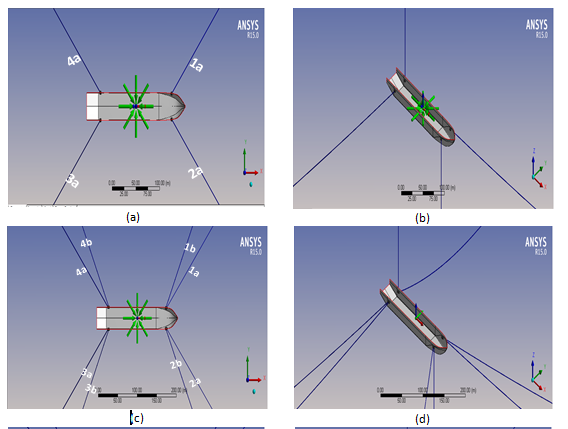

The Aker Smart 2 FPSO is the second FPSO from the Norwegian FPSO operator: Aker Floating Production, and will operate for Reliance in India. This FPSO will be moored with a mooring system catenary to the seabed. In its operation, the FPSO will be influenced by dynamic loads such as sea waves, ocean currents and wind on the mooring rope structure periodically. This may cause damage to the structure mooring line which influences the performance of the operational structure. The aim of this research is to investigate motion trajectory (surge & sway), mooring line stress, and deterministic fatigue on the mooring system catenary by making comparisons using variations in quantities mooring line. Dimensions mooring line type chain on fairlead with varying amounts mooring line namely 4x1, 4x2, and 4x3 which will then be analyzed fatigue damage-his. Numerical observations of FPSO motion on following seas, stern quartering seas, beam seas, bow quartering seas, and head seas show Response Amplitude Operator from movement surge, sway, heave, roll, pitch, and yaw due to harsh environments with Hs = 2.0 meters and T = 12 seconds. Observation Motion Trajectory it is found that the greater the number mooring line then value DOffset or movement surge & sway will get smaller. Meanwhile, in observation Mooring Line Stress and Fatigue Damage obtained both are directly proportional where the greater the tension mooring line the greater the damage. This is because the mass of the rope used is not proportional to displacement boat. And in this numerical analysis simulation it only reaches the initial movement, namely at 100 seconds, where the ship's condition has not yet reached the stable condition it should be.

Downloads

Article Details

This work is licensed under a Creative Commons Attribution 4.0 International License.

References

J. Sade, “Literature Study Of The Effectiveness Of Flexible Pads As Submarine Pipeline Protection Due To Anchor Falls”, CBCER, vol. 1, no. 2 Desember, pp. 1–9, Dec. 2023.

F. M. Assidiq, D. Paroka, M. Z. Muis, and S. Klara, "Fatigue Analysis of Catenary Mooring System due to Harsh Environment in Head Seas", EPI International Journal of Engineering, Vol. 1, half. 30-38,

F. Husain, “Impact and Failure of Internal Pressure of Pipe Connections C Influenced by Sea Water”, CBCER, vol. 1, no. 2 Desember, pp. 68–77, Dec. 2023.

H. Hamzah, “Study Of The Effectiveness Of Subsea Pipeline Leak Detection Methods”, CBCER, vol. 1, no. 2 Desember, pp. 45–56, Dec. 2023.

M. I. Afdhal, U. Budiarto, I. P. Mulyatno, "Optimization of Spread Mooring Design with Line Variation Configurations for Six Degrees of Freedom (DOF) Movement on Floating Storage and Offloading (FSO) Ships" Journal of Shipping Engineering, Vol. 7, p. 86, 2019.

N. Arifannisa, N. Syahroni, M. Murtedjo, "Fatigue Life Analysis Of Anchor Chain Single Point Mooring 3", Final Project of the Department of Marine Engineering, FTK-ITS, pp. 50-54, 2016.

M. F. Bin Yusup, “Risk Evaluation and Damage Mitigation in Subsea Pipelines: A Literature Review of Concepts, Applications, and Challenges”, CBCER, vol. 1, no. 2 Desember, pp. 97–100, Dec. 2023.

M. Riayadh, “Literature Review on Integrity Management of Subsea Pipelines Operating Beyond Design Life”, CBCER, vol. 1, no. 2 Desember, pp. 88–92, Dec. 2023.

J. Sade, “Review of Marine Pipe Repair Methods in Indonesia”, CBCER, vol. 1, no. 2 Desember, pp. 10–17, Dec. 2023.

S. Rismarini, N. Syahroni, M. Murtedjo, "Fatigue Life Analysis Of Yoke Arm Construction On The External Turret Mooring System Fso Ladinda", Final Project of the Department of Marine Engineering, FTK-ITS, page 33, 2016.

Suryadi, Y., & Kim, M. H. "Fatigue life assessment of FPSO mooring systems under different metocean conditions." Ocean Engineering, 160, 234-245, (2018).

Li, Q., & Wei, Y. "A numerical study on the fatigue damage of mooring lines for a deepwater FPSO." Journal of Offshore Mechanics and Arctic Engineering, 139(4), (2017).

Jiang, H., & Li, Y. "Comparative analysis of mooring system performance for FPSOs in ultra-deepwater." Marine Structures, 64, 64-82, (2019).

F. Husain, “Reliability Analysis Of Subsea Pipelines In High Wave Random Conditions”, CBCER, vol. 1, no. 2 Desember, pp. 78–83, Dec. 2023.

. Zhang, X., Li, Y., & Li, C. "Influence of water depth on the dynamic response of FPSO mooring systems." Ocean Engineering, 166, 1-13, (2018).

T. Rachman, “Feasibility Study Of Subsea Pipeline Crossing Plan”, CBCER, vol. 1, no. 2 Desember, pp. 57–67, Dec. 2023.

H. Hamzah, “Study On The Application Of The Articulated Concrete Block Mattresses Method As Subsea Pipeline Protection”, CBCER, vol. 1, no. 2 Desember, pp. 37–44, Dec. 2023.

Yang, C., & Wang, T. "Numerical investigation of fatigue damage in mooring lines of an FPSO under different environmental conditions." Ships and Offshore Structures, 15(8), 1037-1049, (2020).

A. Y. Kyew, “Problems and Solutions in Improving Subsea Pipeline Competency and Quality: A Comprehensive Literature Review”, CBCER, vol. 1, no. 2 Desember, pp. 93–96, Dec. 2023.

Cheng, L., & Zhang, Z. "Fatigue analysis of deepwater FPSO mooring lines under random wave loading." Ocean Engineering, 112, (2016).

S. Rahman, “Vibration Characteristics and Reduction Analysis of the Lifting Pipe Below Sea Wave”, CBCER, vol. 1, no. 2 Desember, pp. 18–28, Dec. 2023.

N. Zin Latt, “ Literature Review of Concepts, Applications, and Challenges in Subsea Pipeline Risk and Reliability Management”, CBCER, vol. 1, no. 2 Desember, pp. 84–87, Dec. 2023.