Analysis Of Needs And Placement Of Zinc Anode For New Ferry Ship Buildings

Main Article Content

Abstract

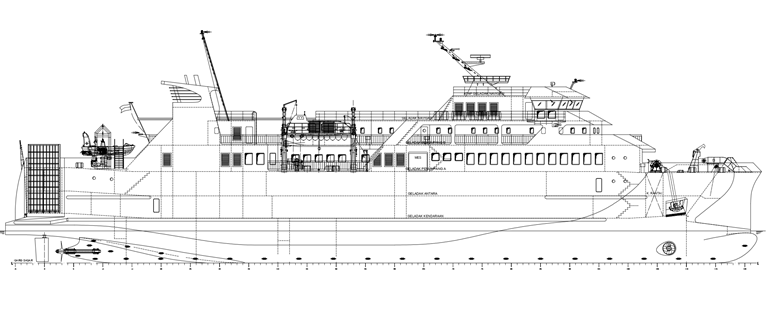

Marine structures (ships, offshore platforms, underwater pipes and other floating structures) in operation are not protected from corrosion. One of the biggest sources of damage to ships is caused by seawater corrosion. Until now, the use of iron and steel as the main materials for shipbuilding is still dominant. Corrosion is a degradation process of a metal due to chemical reactions between the metal and its environment. The aim of this research is how to determine the need for zinc anode and efficient installation distance as well as the costs required in procuring cathodic protection. Cavitation is a factor that often occurs around propellers or propellers. When the propeller or propeller rotates in the water, the low pressure around the surface of the propeller can cause water vapor to form and turn into cavitation bubbles. When these bubbles burst, the erosion effect on the surface of the affected object will quickly corrode. So that the installation of the sacrificial anode at the stern is installed slightly tightly. The method used to control the rate of corrosion is by protecting the steel plate using cathodic protection. Therefore, every ship that is built needs to have zinc anode planning to control the rate of corrosion on the ship's steel plates. The number of zinc anodes required for a new construction ship with a length of 72.76 m, a width of 14 m and a draft height of 3.30 m is 55 with an addition of 30% of the total number at the stern due to the cavitation factor. The design life of the zinc anode protection is 2.5 years with a longated flush mounted (welded type) type s-8, dimensions (300 mm × 150 mm × 25 mm) weighing 8 kg. The installation distance is 3 m and 1.3 m with the installation cost being IDR. 40,530,000.

Downloads

Article Details

This work is licensed under a Creative Commons Attribution 4.0 International License.

Accepted 2024-06-28

Published 2024-06-28

References

Ariani, B. Pengantar Korosi Perkapalan. Banda Aceh, Aceh: Syiah Kuala University Press, (2021).

Beni Hartanto, S. Pemasangan Zinc Anoda Protection (ZAP) sebagai Perlindungan Aktif Korosi Kapal. Majalah Ilmiah Bahari Jogja, Vol.21, No.1, 21-27, 2023

Biro Klasifikasi Indonesia, Guidance for The Corrosion Protection and Coating System, Volume G, Chapter 1, Section 8 B.2, Edition 2019, BKI, Jakarta, 2019

Carlton, J. Marine Propellers and Propulsio Second Edition. USA: Elsevier Ltd, (2007).

Dahlstrom, D. D. Marine Corrosion Protection Guidebook. Amsterdam, Belanda: Elsevier, (2011).

Dwisetiono, & Mahendra, T. I. Proteksi Katodik Mennggunakan Zinc Anode Untuk Menghambat Korosi pada Lambung Kapal Port LINK VII Jakarta. Jurnal Teknik dan Sains Fakultas Teknologi Fakultas Teknologi Lingkungan dan Mineral Universitas Teknologi Sumbawa, Volume 3 Nomor 1, 56-62, (2022).

Equipment,I.M. Dasar Penyebab Korosi Kapal. Diakses dari Inameq.com: https://inameq.com/hullandoutfitting/painting/dasarpenyebabkorosikapal/, (2023).

Gapsari, F. Pengantar Korosi. Malang: UB press, (2017).

Ghali, E. Corrosion Prevention and Protection:Practical Solutions. New Jersey, America: Wiley, (2004).

Hermawan, H. Pengantar Proteksi Katodik. Canada : Laval University Press, (2019).

Hetharia, Perencanaan Kapal 1. Ambon: Universitas Pattimura Ambon, (2019).

LEMBAYUNG, L. Tahap Pmebuatan Kapal Baru. Diakses dari latarlembayung.wordpress.com: https://latarlembayung.wordpress.com/2012/11/25/tahap-pembuatan-kapal-baru/, (2023).

Made Rai Ratih Cahya, P. a. Penerapan Hitungan Volume Metode Simpson untuk Menghitung Volume Kapal dan Topografi Darat. Jurnal Rekayasa Hijau, No.1, Vol.2, 90-100, (2018).

Molland, A. F. Ship Resistance and Propulsion. Cambridge: University Press, (2011).

R.Roberge, P. Corrosion Engineering: Principle and Practice. Wiley: McGraw Hill, (2008).

Roberge, P. R. Handbook of Corrosion Engineering. United States of America: McGraw-Hill, (1999).

Sasono, E. J. Efektivitas Penggunaan Anoda Korban Paduan Aluminium Pada Pelat Baja Kapal Aisi E 2512 Terhadap Laju Korosi di Dalam Media Air Laut. Tesis, 1-91, (2010).

Sasono, E. J. Aplikasi Metode Numerik Dalam Perhitungan Luas dan Volume Badan Kapal Yang Berada di Bawah Permukaan Air Laut. Kapal, Vol.3, No.3, 83-88, (Oktober2006).

Sunarto, & Septian, D. Analisa Kebutuhan Anoda Korban Seng Pada Plat Bottom Kapal di Pt. Indonesia Marina Shipyard. Jurnal Keilmuan dan Terapan Teknik , Volume 04, Nomor 01, 92-108, (2015).

Sunarto, D. S. Analisa Kebutuhan Anoda Korban Seng Pada Plat Bottom Kapal di Pt. Indonesia Marina Shipyard. Wahana Teknik, Volume 04, Nomor 01, 92-108, (Juni 2015).

Supomo, H. Korosi Perkapalan. Jawa Timur: Airlangga University Press, (2023).

Uhlig, H. H., & Revie, R. W. Corrosion and Corrosion Control: An Introduction to Corrosion Science and Engineering. New Jersey, America: Wiley, (2008).

Widianingrum, W. Analisis Peletakan dan Kebutuhan Proteksi Katodik Pada Mooring Buoy di Pertamina Fuel Terminal Luwuk. Jurnal Inovasi Sains dan Teknologi Kelautan, Volume 2, Nomor 2, (2021).

S. Suardi, “Freeboard and Trim Measurement: a Case Study of Landing Craft Tank Conversion to Ship Power Plan”, zonalaut, vol. 5, no. 1, pp. 1-6, Mar. 2024.

A. Fadillah and N. Nadia, “Seakeeping Of A 60 Gt Cast Nets Fishing Vessel At Muara Angke Fishing Port”, zonalaut, vol. 5, no. 1, pp. 15-22, Mar. 2024.